The installation of stainless steel water pipe clamps is a common and important project, and choosing the right tools can greatly improve work efficiency and safety. Before proceeding with this installation, we need to prepare the following tools:

1. Pliers:

Choosing a reliable pair of pliers is crucial. Especially, we need a pipe clamp with sufficient grip and easy operation, which can help us more easily grasp the force during installation.

2. Pipe cutter:

This tool is essential as we can use a pipe cutter to cut stainless steel water pipes into the desired length. Choosing a sharp pipe cutter can ensure smooth cutting and reduce subsequent processing work.

3. Ink pen/ruler:

Before installing the water pipe, we need to use an ink pen or ruler for measurement and marking. This will help us ensure the accuracy and precision of the water pipes, avoiding waste and errors.

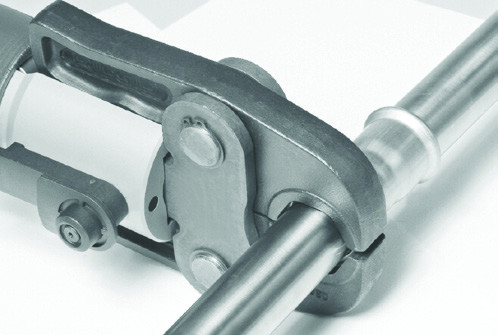

4. Power multiplier:

Due to the hardness of thin-walled stainless steel water pipes, we need to use a force multiplier to apply sufficient force for clamping operation. Note that choosing a high-quality and easily adjustable multiplier is very important.

5. Hand drill/electric wrench:

When installing thin-walled stainless steel water pipes with double clamping, we usually need to use a hand drill or electric wrench for some special procedures, such as fixing bolts and nuts on the water pipe.

The above tools are essential for the installation process of thin-walled stainless steel water pipes with double clamping pressure. Proper and appropriate use of them will help us better complete the installation work. Of course, in addition to tools, we also need to understand the following steps and techniques:

Step 1: Preparation work

Before the formal installation, it is necessary to ensure that the work area is clean and tidy, without any debris or obstacles. At the same time, it is necessary to inspect and clean the required tools to ensure their proper operation and functionality.

Step 2: Measure and cut the water pipe

Measure the water pipe with an ink pen or ruler and cut it to the appropriate length as needed. Use a pipe cutter to ensure straight and smooth cutting, and clean the inner and outer surfaces of the pipe.

Step 3: Install pipe clamps and clamps

Firstly, fix the pipe clamp onto the water pipe to ensure its correct position and tight fit. Then, use a multiplier to apply appropriate pressure and firmly double clamp the clamp onto the water pipe to ensure sealing and stability.